“With the firm awareness that quality is the pillar of any industry, we have skilled labor to ensure the quality of final products of our clients, offering professional services at competitive costs.”

About us

We are a 100% Mexican company, located in the city of Nuevo Laredo, Tamaulipas and dedicated to providing manufacturing and quality control services to companies in the local, national and foreign industry.

We started operations on May 20th of 2015 as an individual with a total of 6 employees offering the services of fasteners recovery for the automotive industry, freight, machining and welding services in general.

For November of 2016, the company is constituted as a corporate entity, thanks to the efforts of our employees, provision, continuous improvement and the confidence of our clients, we expand our operations in manufacturing processes inside and outside our customers’ facilities, increasing our work base to 40 employees.

By September of 2017, we added quality control services increasing our staff to 60 collaborators; we have a team willing to serve you responsibly and integrate in the solution of their problems so that they can achieve their goals.

Mission

Being a company that provides a quality service and immediate solutions exceeding the needs and expectations of our customers at the best cost in the market.

Vision

To be a leading company in providing Manufacturing and Quality control services to the industry of Nuevo Laredo and the region providing integral solutions to our customer.

Services

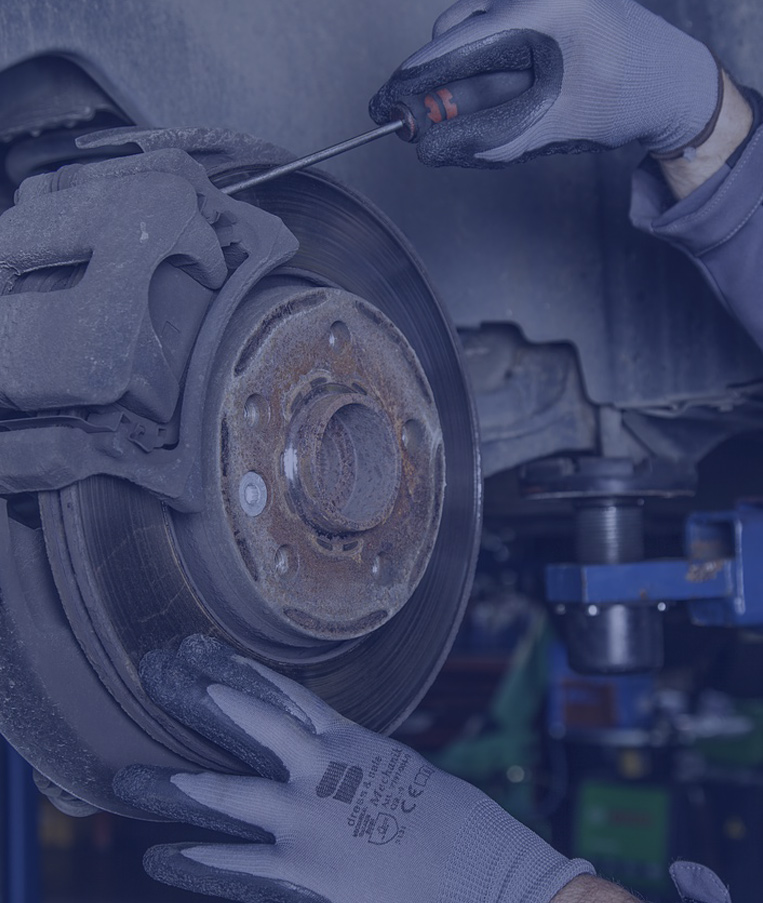

Inspection

Sorting & Containment

Rework

Labeling & Packaging

Salvage Programs

Kits Assembly

Need kits? We are your solution, with the necessary infrastructure and trained labor to perform these types of works.

Supplier Representation

We represent your brand and your products. When talking of quality issues fast response is a must, but is material being handled correctly? is assembly process properly? With INGSERMA you can have an on-site collaborator with all the needed knowledge of your product to solve any quality issue.

Cleaning of Components

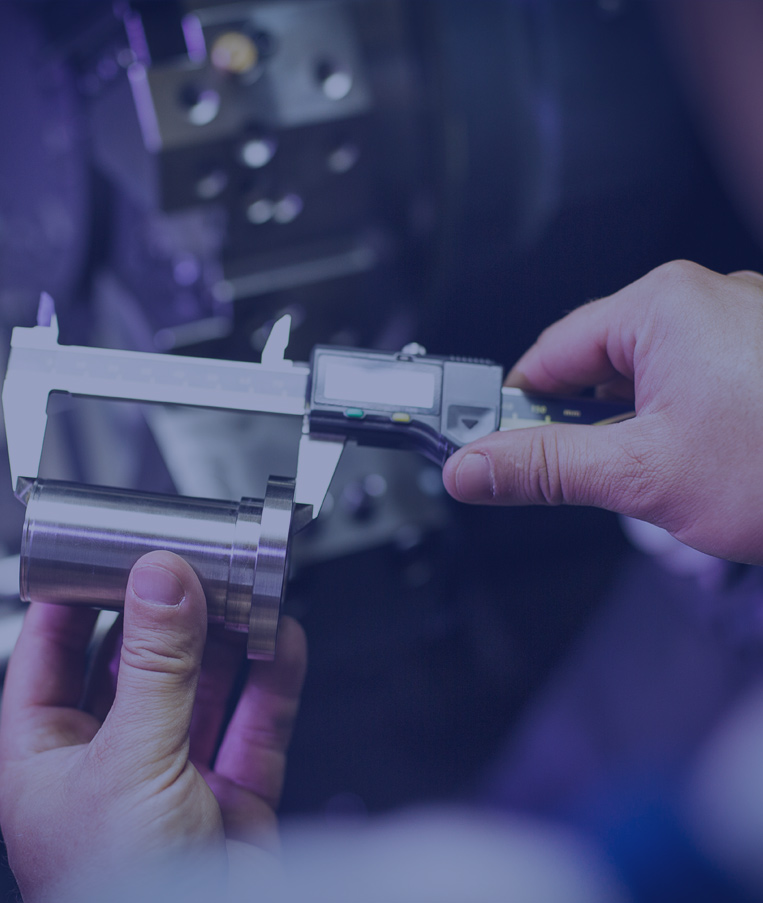

Centerless Grinding

Centerless Grinding is a form of cylindrical grinding that allows high trough-put production with excellent roundness, low RA/RMS Surface finishes and real low diameter tolerances.

Cabinet Sand Blasting

Get rid of oxide, rust, coatings, or just clean your components for any manufacturing process needed. Our Cabinets will fit any component under the next dimensions: 18” x 24” x 32”.

Materials that can be processed: All metals (Including Copper, Brass, Nickel, Carbon, Stainless Steel, Alloys, Aluminum) & Plastics.

Manual Assemblies

CNC Machining Services

Solutions

An On-Site service where our staff stays in customers facility as required to cover specific shifts with specific responsibilities.

Our Customers

Contact us

ADDRESS

Zaragoza #3314 Col. Juárez

Nuevo Laredo Tamaulipas, Mx. CP. 88209

Mobile +52 (867)729-1249

+52 (811) 681-1835

Email ventas@ingserma.com